How Fiber Laser Welding Machines Work: Precision, Efficiency, and Innovation

Source:razorteklaser Time:2025-04-27

In today’s fast-paced manufacturing landscape, precision and efficiency are non-negotiable. At Razortek, we pride ourselves on delivering cutting-edge solutions like fiber laser welding machines that redefine industrial capabilities. But how exactly do these advanced systems work, and why are they revolutionizing industries from automotive to aerospace? Let’s dive into the science behind the innovation.

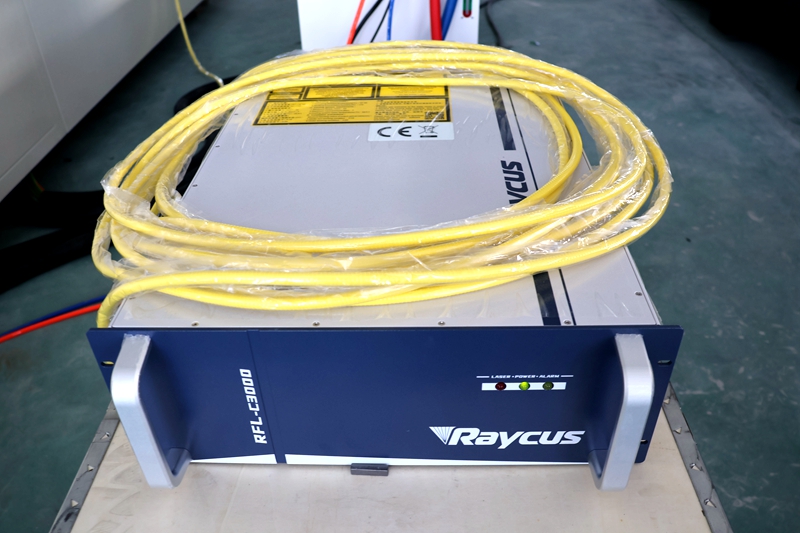

The Science of Fiber Laser Welding

Fiber laser welding machines harness the power of high-intensity laser beams generated through optical fibers doped with rare-earth elements (e.g., ytterbium). Here’s a simplified breakdown of the process:

1. Laser Generation:

Electrical energy is converted into light energy within the fiber optic cable. The doped fiber amplifies this light, creating a concentrated, coherent laser beam.

2. Beam Delivery:

The laser beam travels through a flexible fiber optic cable, ensuring minimal energy loss and precise directionality.

3. Focusing Optics:

The beam is directed through a collimating lens and focused onto the workpiece using a high-precision cutting or welding head.

4. Material Interaction:

When the laser strikes the material’s surface, its energy is absorbed, rapidly heating and melting the targeted area. A molten pool forms, fusing the materials together with exceptional accuracy.

5. Cooling and Solidification:

The molten pool cools almost instantly, creating a strong, clean weld seam with minimal thermal distortion.

Why Choose Fiber Laser Welding?

1. Unmatched Precision: Achieve micron-level accuracy, perfect for delicate components in electronics or medical devices.

2. Speed and Efficiency: Process materials up to 10x faster than traditional methods, slashing production timelines.

3. Versatility: Weld everything from reflective metals (aluminum, copper) to complex alloys with ease.

4. Eco-Friendly: Reduced energy consumption and no consumables like filler materials.

Applications Across Industries

Fiber laser welding machines are transforming sectors globally:

1. Automotive: Battery welding for EVs, lightweight chassis components.

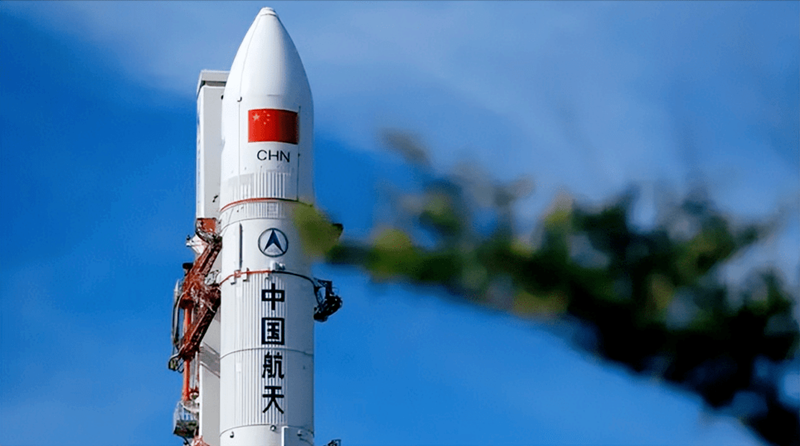

2. Aerospace: High-strength, fatigue-resistant joints for critical parts.

3. Electronics: Hermetic sealing of sensors and micro-components.

4. Medical: Sterile, burr-free welds for surgical tools and implants.

Don’t let outdated technology hold you back. Contact our team today to discover how our solutions can elevate your manufacturing process!