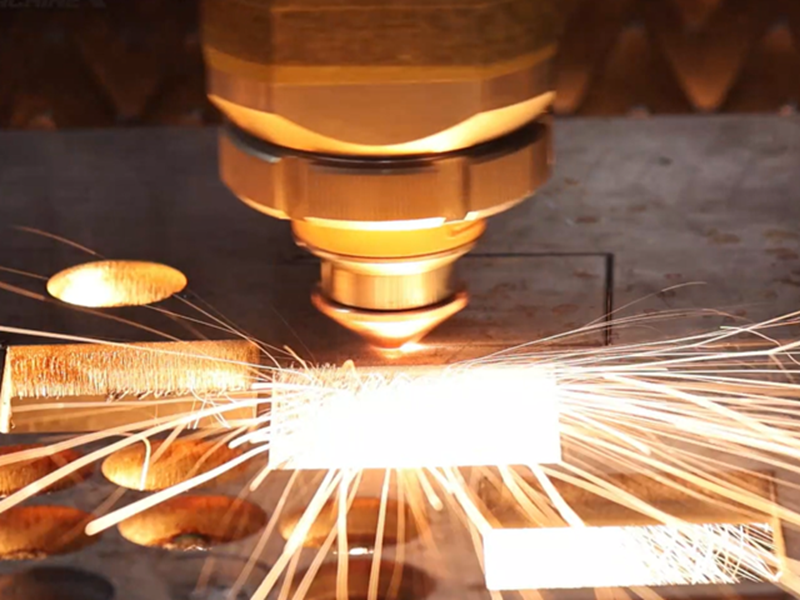

Fiber Laser Cutting Machines: Powering Precision Across Industries

Source:razorteklaser Time:2025-07-04

Fiber laser cutting technology has revolutionized material processing, offering unprecedented speed, precision, and versatility. At Razortek, our advanced fiber laser cutting systems are engineered to tackle the most demanding challenges across diverse sectors. Here's a glimpse into how this powerful technology is transforming manufacturing:

1. Automotive Manufacturing: Driving Efficiency & Innovation

Application: Cutting complex structural components (chassis parts, brackets), intricate body panels, exhaust system parts, and safety components (airbag housings).

Advantages: Exceptional speed for high-volume production, micron-level precision for perfect fitment, ability to cut high-strength steels and lightweight alloys, minimal heat-affected zone preserving material integrity. Reduces secondary operations and scrap rates significantly.

2. Aerospace & Defense: Meeting Stringent Standards

Application: Fabricating turbine engine components, intricate airframe parts (ribs, brackets), heat shields, lightweight structural elements, and specialized defense equipment parts from titanium, Inconel, aluminum, and composites.

Advantages: Unmatched precision for complex geometries and tight tolerances, clean cuts requiring minimal post-processing, ability to cut reflective materials effectively, superior process control ensuring material properties are maintained for critical flight safety.

3. Metal Fabrication & Job Shops: The Backbone of Versatility

Application: Cutting sheet metal for enclosures, frames, brackets, signage, decorative panels, architectural elements, and custom parts from mild steel, stainless steel, and aluminum.

Advantages: Rapid processing speeds increase throughput and profitability, ability to handle diverse materials and thicknesses (typically up to 25mm mild steel, 20mm stainless, 20mm aluminum with high-power systems), minimal setup time between jobs, high edge quality reduces finishing labor. Ideal for prototypes, small batches, and high-mix production.

4. Electronics & Consumer Goods: Precision on a Smaller Scale

Application: Cutting intricate components for enclosures, heat sinks, chassis, connectors, smartphone internal brackets, appliance panels, and decorative trim from thin-gauge metals and some specialized alloys.

Advantages: Ultra-fine focus allows for micron-level precision on delicate features, very small kerf width minimizes material waste, high speed for mass production, non-contact process prevents part deformation on thin materials. Essential for miniaturization trends.

5. Energy Sector (Oil & Gas, Renewable): Building Robust Infrastructure

Application: Cutting pipeline components, pressure vessel parts, flanges, heat exchanger plates, wind turbine structural elements (towers, housings), and solar panel mounting systems.

Advantages: Ability to cut thick plates efficiently (high-power systems handle 30mm+ mild steel), clean cuts on high-alloy steels and corrosion-resistant materials, consistent quality for critical pressure-containing parts, high productivity for large-scale projects.

6. Medical Device Manufacturing: Enabling Life-Saving Precision

Application: Fabricating surgical instruments (scalpels, forceps, clamps), implant components, specialized tooling, diagnostic equipment parts, and enclosures from medical-grade stainless steel, titanium, and nitinol.

Advantages: Exceptional cut quality with smooth, burr-free edges crucial for biocompatibility and sterility, ability to cut complex, tiny geometries with high repeatability, minimal heat input preserves material properties and prevents distortion. Vital for meeting stringent regulatory standards.

Why Choose Razortek Fiber Lasers?

Our commitment goes beyond providing cutting machines; we deliver comprehensive manufacturing solutions. Razortek fiber laser cutters are renowned for:

Industry-Leading Precision & Speed: Maximize throughput without sacrificing quality.

Robust Reliability & Low Operating Costs: Minimize downtime and cost-per-part.

Intuitive Software & Automation Integration: Simplify operation and boost productivity.

Superior Beam Quality & Cutting Performance: Achieve unmatched results across materials.

Dedicated Support & Expertise: Partner with us for seamless integration and optimization.

Ready to transform your production capabilities? Explore our range of fiber laser cutting solutions and discover how we can empower your industry: https://www.razortekcnc.com/Laser_Machine/Fiber_laser_cutter/