Common Problems About Fiber Laser Cleaner

Source:razorteklaser Time:2025-07-21

In order to enhance everyone's understanding of fiber laser cleaning machines, Razortek has compiled several common problems in metal processing and provided solutions for customers to adjust when these production issues actually arise.

I. What is the working principle of laser cleaning machine?

Answer:

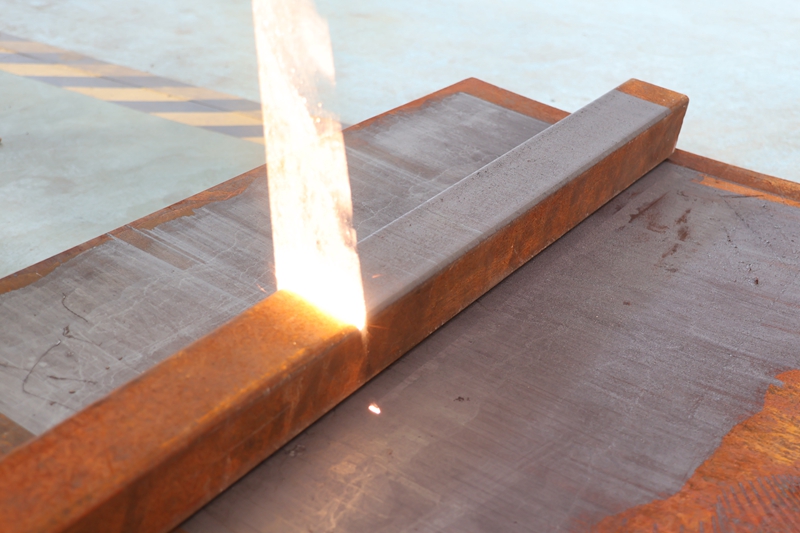

The laser cleaning machine mainly uses the instantaneous high-temperature corrosion generated by the laser beam on the surface of the product to melt surface substances such as rust, coatings, oil stains, etc. It is a new technology based on the interaction effect between laser and matter. Unlike traditional mechanical cleaning, chemical cleaning, and ultrasonic cleaning methods, it does not require any CFC organic solvents that destroy the ozone layer. It is pollution-free, noiseless, and harmless to human health and the environment. It is a truly green and environmentally friendly cleaning technology.

II. What materials can laser cleaning machines clean?

Answer:

1. Laser cleaning machines can be used not only to clean organic pollutants, but also to clean inorganic substances, including metal rust, metal particles, dust, etc.

2. It has good cleaning effect on materials such as iron, carbon steel plate, stainless steel plate, mold, steel gear, aluminum plate, and putty free paint layer;

3. Can remove dust and attachments from the surface of the stone statue;

4. Cleaning of residual rubber molds;

5. Meet the requirements for equipment cleaning in the shipbuilding industry, automotive parts, rubber molds, machine tools, tire molds, tracks, environmental protection industries, and other fields;

III. What is the difference between pulse laser cleaning and continuous laser cleaning?

Answer:

Pulse laser cleaning machine:

The characteristic of pulse laser is that the energy is highly concentrated in a short period of time, forming a series of short and strong light pulses. High peak power, minimal heating effect, high precision, suitable for microfabrication. After cleaning the dirt, it can achieve zero damage to the substrate, suitable for cleaning products with high surface requirements on the substrate; For example, cleaning ancient artifacts, non-metallic materials, or substrates that require no damage to the surface of the material.

Continuous laser cleaning machine:

It continuously outputs a stable beam of light without significant pulse intervals. Its output power is relatively stable and suitable for situations that require a stable light source for a long time. It has high cleaning efficiency and is suitable for large-scale cleaning, but it may cause some damage to the surface. Generally speaking, continuous laser cleaning is required for large-scale cleaning of rust and other materials.

IV. Does the fiber laser cleaning machine have optimal parameters and distances when cleaning materials?

Answer:

The cleaning machine has an optimal distance for cleaning, and the cleaning parameters need to be adjusted according to the material being cleaned.

V. Can a fiber laser cleaning machine remove soap lubricant from metal?

Answer:

Continuous laser cleaning cannot be used to clean soap lubricants.

Pulse-type laser cleaning can clean solids without attachments, but it cannot remove liquids.