Market Development Trends of Fiber Laser Cutting Machines

Source:razorteklaser Time:2025-08-01

Fiber laser cutting technology has revolutionized metal fabrication over the past decade, and its market continues to exhibit strong, dynamic growth. Understanding the key trends shaping this evolution is crucial for businesses seeking a competitive edge. Here's an overview of the primary market development trends:

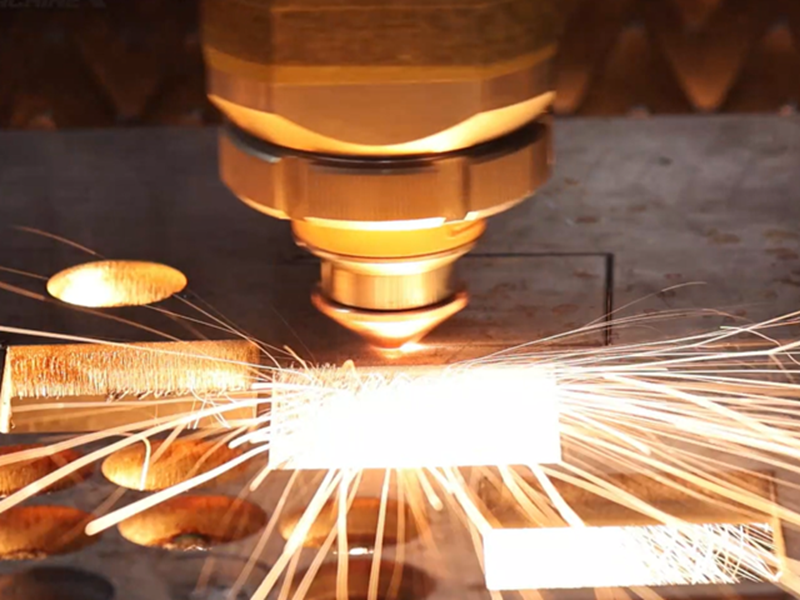

Rapid Power Progression & Enhanced Capabilities:

The relentless push for higher power lasers (now routinely exceeding 30kW and reaching 40kW+) is a dominant trend. This enables dramatically faster cutting speeds, especially on thick materials (steel, aluminum), and expands the range of processable metals and thicknesses. Concurrently, improvements in beam quality and pulse control allow for finer precision, smoother cut edges, and better results on reflective materials and thin sheets.

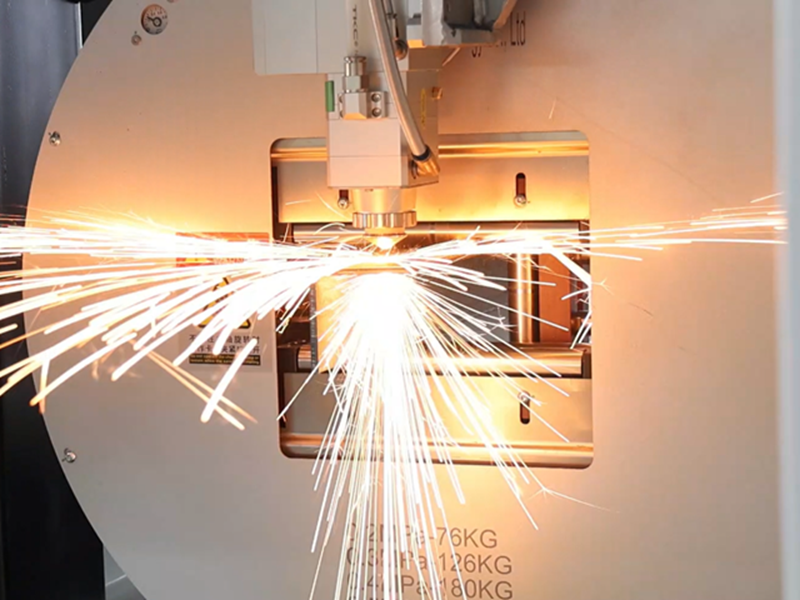

Smart Manufacturing & Automation Integration: Fiber laser cutters are increasingly becoming central nodes in smart factories. Key developments include:

1. IoT Connectivity: Machines equipped with sensors for real-time monitoring of performance, consumables status (laser source, optics), and predictive maintenance needs.

2. AI & Machine Learning: Algorithms optimizing cutting paths in real-time for speed and material yield, predicting potential errors, and enabling adaptive process control.

3. Seamless Automation: Tighter integration with robotic loading/unloading systems, material storage towers (AS/RS), and downstream processes (bending, welding) for true lights-out manufacturing and reduced labor costs.

Focus on Cost Efficiency & Sustainability: Market pressure demands lower operational costs:

1. Energy Efficiency: Fiber lasers inherently consume significantly less power than CO2 lasers. Newer models push this further, offering "Eco" modes and smarter power management.

2. Reduced Consumables & Maintenance: Advancements in laser source design (e.g., semiconductor pumping) and cutting head technology aim to extend component life and minimize downtime/costs.

3. Material Optimization: Nesting software is becoming more sophisticated, maximizing material utilization and minimizing scrap – a significant cost and sustainability factor.

Democratization & Accessibility:

While high-power machines target large industrial users, there's significant growth in the mid-range (2kW - 6kW) and entry-level (<2kW) segments. More affordable, compact, and user-friendly machines are opening the technology to smaller job shops and workshops, expanding the overall market base.

Application Diversification: Fiber lasers are moving beyond traditional sheet metal cutting:

1. Tube & Profile Cutting: Dedicated systems with sophisticated programming for complex 3D shapes are seeing high demand, driven by construction, automotive, and furniture industries.

2. Micromachining: Ultrafast (pulsed) fiber lasers enable high-precision applications in electronics, medical devices, and semiconductors.

3. Additive Manufacturing: Fiber lasers are key components in some Directed Energy Deposition (DED) metal 3D printing systems.

Geographic Market Shifts: While China remains the largest producer and consumer, significant growth is occurring in:

1. Southeast Asia: Rapid industrialization and manufacturing investment.

2. India: Expanding domestic manufacturing capabilities ("Make in India").

3. North America & Europe: Driven by reshoring trends, defense spending, and adoption of automation for high-mix, low-volume production.

Conclusion

The fiber laser cutting market is characterized by relentless technological advancement, driving towards higher productivity, greater intelligence, lower operational costs, and broader accessibility. The integration of smart features and automation is no longer a luxury but a necessity for staying competitive. Companies that embrace these trends – investing in higher capabilities, smarter systems, and sustainable practices – will be best positioned to capitalize on the expanding opportunities across diverse industries and global markets.

At Razortek, we are at the forefront of these developments. We continuously innovate our fiber laser cutting solutions, integrating cutting-edge power sources, intelligent software, and automation readiness to empower your manufacturing for the future.