Choosing the Right Power: Your Guide to Fiber Laser Cutting Machine Performance

Source:razorteklaser Time:2025-09-03

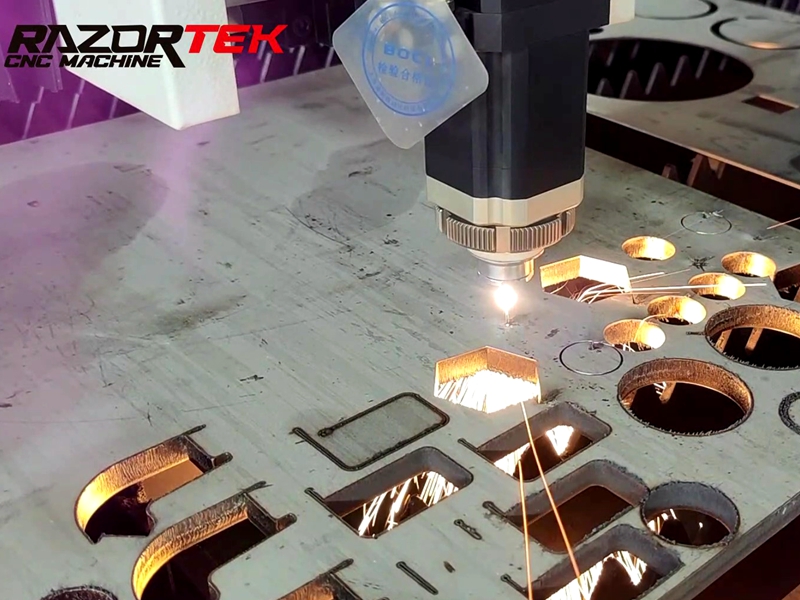

Selecting a fiber laser cutting machine is a significant investment, and one of the most critical decisions revolves around laser power. Getting the power right directly impacts your productivity, cut quality, and operational costs. But how do you determine the optimal wattage for your specific metal cutting needs? Let's break down the key factors.

Why Power Matters: The Core Equation

Laser power (measured in Watts - W, Kilowatts - kW) is essentially the intensity of the laser beam. It fundamentally influences:

1. Material Thickness & Type: Higher power cuts thicker materials. Stainless steel and mild steel require less power for a given thickness than aluminum or reflective metals like copper or brass.

2. Cutting Speed: More power generally equals faster cutting speeds, especially on thicker materials. This boosts throughput.

3. Edge Quality & Precision: Optimal power delivers clean, smooth cuts with minimal dross (residue) and a narrow kerf (cut width). Insufficient power leads to rough edges or incomplete cuts; excessive power can cause excessive melting, wider kerf, or heat distortion on thin sheets.

4. Operating Costs: Higher power machines consume more electricity and may require higher-pressure assist gases (like Nitrogen or Oxygen). Balancing power with actual needs optimizes running costs.

Matching Power to Your Application: Finding the Sweet Spot

Here's a general guide to common power ranges and their typical capabilities:

1. Lower Power (1 kW - 2 kW):

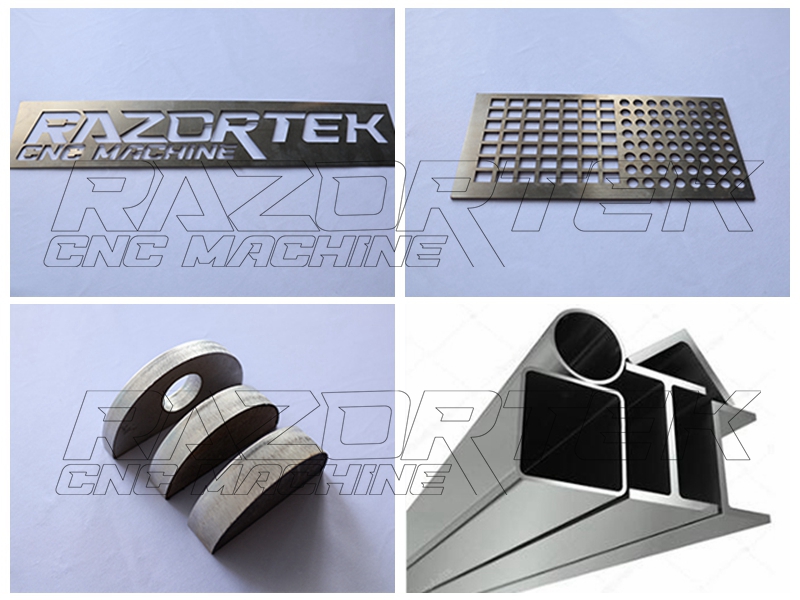

Ideal For: Thin sheet metal fabrication.

Materials: Mild steel (up to 4-6mm), Stainless steel (up to 3-4mm), Aluminum (up to 3mm).

Strengths: Excellent speed and precision on thin gauges, lower initial investment, lower operating costs. Perfect for intricate designs, electronics, signage, and HVAC ductwork.

Limitations: Cannot effectively process thicker materials.

2. Medium Power (3 kW - 6 kW):

Ideal For: The most versatile range, handling a wide mix of jobs. Popular choice for job shops and general fabrication.

Materials: Mild steel (up to 12-20mm), Stainless steel (up to 8-12mm), Aluminum (up to 8-12mm). Handles brass and copper (thinner gauges) more effectively than lower powers.

Strengths: Excellent balance of speed, thickness capacity, and cut quality across a broad spectrum. Good cost-effectiveness for mixed-volume production.

Limitations: Cutting very thick mild steel (>20mm) or high-volume thick plate will be slower than higher power options.

3. High Power (8 kW - 15 kW+):

Ideal For: Heavy industrial fabrication, structural steel, pressure vessels, and high-volume production focusing on thick plates.

Materials: Mild steel (up to 25-40mm+), Stainless steel (up to 20-25mm+), Aluminum (up to 20-25mm+).

Strengths: Dramatically increased cutting speeds on thick materials (often 2-3x faster than 6kW on 20mm steel), ability to tackle demanding heavy plate applications, potential for higher overall throughput in thick-material focused shops.

Limitations: Higher initial investment, higher operating costs (power consumption, gas usage), potential for increased heat input on thinner materials requiring careful parameter tuning. Overkill for shops primarily working with thin sheet.

Key Considerations Beyond Raw Power:

1. Your Material Mix: What metals and what thicknesses do you cut most frequently? Don't choose power based solely on the thickest, rarest job if 90% of your work is thin gauge.

2. Production Volume & Speed Requirements: Do you need maximum throughput on thick plate, or is precision on thin sheet your priority?

3. Cut Quality Needs: What level of edge smoothness and perpendicularity is required for your finished parts? Higher power often allows cleaner cuts on thick materials with optimized settings.

4. Assist Gases: Higher powers often work best with higher purity/pressure gases for optimal results, especially on thick materials or when cutting with Nitrogen for oxidation-free edges. Factor in gas costs.

5. Machine Quality & Optics: A well-built machine with high-quality optics (cutting head, lenses) will deliver the full potential of its rated power more consistently and reliably than a lower-quality machine.

Making the Smart Choice

There's no single "best" power. The right choice hinges on your unique production profile. Ask yourself:

1. What are my primary materials and their thickness ranges?

2. What are my daily/weekly production volume targets?

3. What level of cut quality is essential?

4. What is my budget for both acquisition and operational costs?

Partnering for Success

Choosing the optimal laser power is crucial for maximizing your return on investment. At Razortek, we don't just sell machines; we provide solutions. Our experts are ready to analyze your specific cutting requirements, material usage, and production goals to recommend the perfect fiber laser cutting machine – with the ideal power level – to drive your efficiency and profitability.

Contact Razortek today for a personalized consultation and discover how the right laser power can transform your metal fabrication capabilities.