Fiber Laser Cleaning: Excellent Cleaning Technology

Source:razorteklaser Time:2025-11-14

Fiber laser cleaning can process metal materials such as stainless steel, carbon steel, aluminum alloy, and titanium alloy.

1. Carbon steel, stainless steel:

Rust, paint/varnish, oil stains, oxides.

Widely used in rail transit, mechanical equipment, and other fields. After cleaning, the surface is clean, smooth, and free from damage to the base material.

2. Aluminum: Oxides, Surface Contaminants

Technical Features:

Fiber laser cleaning achieves micro level surface cleaning through beam focusing, especially suitable for small spaces or precision component processing. For example, surface cleaning of non-metallic materials such as semiconductor chips and magnetic materials can also be achieved through similar technologies.

Specific application scenarios:

1. Metal Surface Rust Removal: It can quickly remove metal oxides and rust layers, suitable for scenarios such as ships and aerospace components.

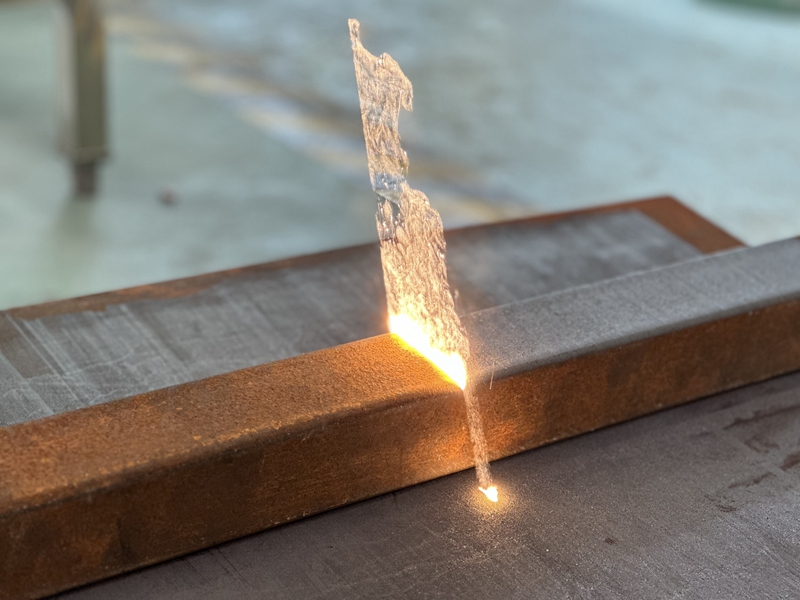

2. Pre- and Post-Welding Treatment: Used to clean surface contaminants before welding and remove oxides and residues after welding, ensuring welding quality.

3. Mold Cleaning: Remove oil stains, resin, and other contaminants from the surfaces of tire molds, electronic molds, and similar materials.

4. Nuclear Power Component Maintenance: Efficiently remove oxides and stains from the surface of nuclear power equipment to ensure operational safety.

5. Cultural Relics Restoration: Remove pollutants from the surface of cultural relics to protect historical artifacts.