Essential Daily Maintenance Tips for Your Fiber Laser Cutting Machine

Source:razorteklaser Time:2025-07-09

Maximizing the performance and lifespan of your fiber laser cutting machine starts with consistent daily care. At Razortek, we prioritize both cutting-edge technology and operational reliability. Follow these key maintenance practices to ensure peak productivity, minimize downtime, and protect your investment.

6 Daily Maintenance Must-Dos:

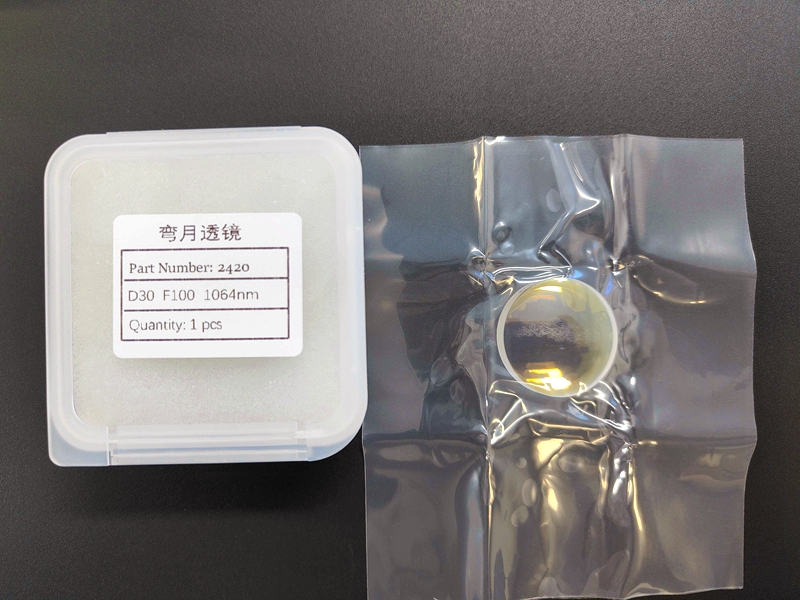

1. Optics Inspection & Cleaning

Gently clean lenses and mirrors before each shift using lens paper and pure isopropyl alcohol.

Check for scratches, dust, or residue – contaminated optics reduce beam quality and cut accuracy.

2. Nozzle and Consumables Check

Inspect nozzles for wear, dents, or debris buildup. Replace damaged ones immediately.

Verify gas pressure and purity levels to maintain consistent cut quality.

3. Cutting Bed and Slat Maintenance

Remove slag, debris, and metal fragments from the bed. Warped or clogged slats cause reflection issues.

Ensure slats are evenly positioned to prevent workpiece instability.

4. Cooling System Monitoring

Confirm coolant levels and temperature (ideally 20–25°C).

Check for leaks and ensure filters are clean to prevent overheating.

5. Rail and Motion System Care

Wipe guide rails and racks daily with a lint-free cloth. Apply lubricant per manufacturer guidelines.

Listen for unusual noises during operation – grinding or squeaking may indicate misalignment.

6. Software and Calibration

Verify laser calibration using test cuts.

Back up cutting programs and update software as recommended.

⚠️ Critical Safety Reminders:

1. ALWAYS power down the laser and disconnect energy sources before maintenance.

2. Wear protective gloves and goggles when handling optics or cleaning chemicals.

3. Never touch electronic components with wet hands.