How to Choose the Right Assist Gas for Your Fiber Laser Cutting Machine

Source:razorteklaser Time:2025-08-11

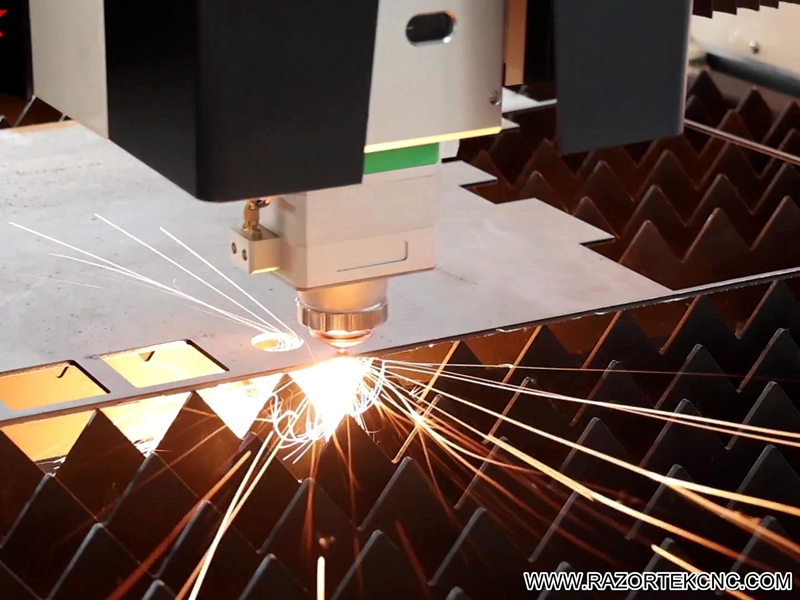

Selecting the optimal assist gas is a critical, yet sometimes overlooked, factor in achieving peak performance with your fiber laser cutting machine. The right gas directly impacts cut quality, edge condition, speed, and operational costs. As a leading manufacturer of fiber laser cutting and welding systems, we understand the nuances. This guide demystifies gas selection to help you maximize your investment.

I. Why Does Assist Gas Matter?

The assist gas, ejected coaxially with the laser beam through the cutting nozzle, serves several vital functions:

1. Eject Molten Material: Blows molten metal out of the kerf (the cut path).

2. Protect Optics: Shields the lens from spatter and fumes.

3. Influence the Cutting Process: Reacts chemically with the material (in the case of oxygen) or acts inertly to cool and protect (nitrogen, argon).

4. Affect Edge Quality: Determines oxidation levels, dross formation, and smoothness.

II. Choosing the Right Gas: Material is Key

The primary factor driving gas choice is the material you are cutting:

1. Mild Steel (Carbon Steel): Best Choice: Oxygen (O₂)

Why: Oxygen reacts exothermically (burns) with the hot iron, significantly adding heat to the cutting process. This allows for faster cutting speeds, especially on thicker plates (typically > 3mm). It also helps blow molten material away effectively.

Considerations: The reaction creates an oxidized cut edge, which is usually darker (grey/black). While generally acceptable for many applications, this oxide layer may need removal if painting or powder coating is required. Edge smoothness might be slightly rougher than with nitrogen.

2. Stainless Steel: Best Choice: Nitrogen (N₂) - High Purity (≥99.95% or better)

Why: Nitrogen acts as an inert shield. It prevents oxidation, resulting in a clean, bright, oxide-free cut edge with minimal dross. This is crucial for stainless steel's corrosion resistance and aesthetic appeal. High purity is essential to prevent contamination and edge oxidation.

Considerations: Higher gas pressures and flows are often needed compared to oxygen cutting. Cutting speeds are generally slower than oxygen-cutting mild steel of equivalent thickness. Consumable costs (gas, nozzles) are higher.

3. Aluminum & Aluminum Alloys: Best Choice: Nitrogen (N₂) - High Purity (≥99.95% or better)

Why: Similar to stainless, nitrogen prevents oxidation, leading to clean, silver-colored, dross-free edges essential for welding or anodizing. Aluminum's high reflectivity and thermal conductivity make a clean, non-reactive gas ideal.

Considerations: Requires high pressure and flow rates. Cutting parameters need careful optimization due to aluminum's properties. Edge quality can be exceptionally good with the right setup.

4. Brass & Copper: Best Choice: Nitrogen (N₂)

Why: Nitrogen provides clean, oxidation-free cuts. The high reflectivity of these materials makes inert gas cutting preferable.

Considerations: Cutting these highly reflective metals requires specific laser parameters and safety considerations. Nitrogen helps achieve acceptable quality.

5. Titanium: Best Choice: Argon (Ar)

Why: Argon is even more inert than nitrogen. Titanium is extremely reactive at high temperatures, and argon provides the best protection against oxidation and embrittlement, which is critical for aerospace and medical applications.

Considerations: Argon is significantly more expensive than nitrogen or oxygen. Requires specialized setup and safety protocols due to titanium's reactivity.

III. Other Key Factors Influencing Gas Choice:

1. Material Thickness:

Thicker Materials: Often benefit from the exothermic boost of oxygen (for mild steel) or require significantly higher pressures and flows of nitrogen to effectively eject molten material.

Thinner Materials: Can often be cut effectively with nitrogen for a cleaner edge, even on mild steel, or with lower oxygen pressures.

2. Required Edge Quality:

Prioritizing a clean, oxide-free, weld-ready edge? Nitrogen (or Argon) is usually mandatory.

Is a slightly oxidized edge acceptable for the application? Oxygen might be the more economical choice for mild steel.

3. Cost Considerations:

Oxygen: Generally the least expensive gas option.

Nitrogen: More expensive than oxygen; cost increases significantly with required purity and flow rates. On-site nitrogen generators can be a cost-effective solution for high-volume users.

Argon: The most expensive option.

4. Nozzle Selection & Pressure/Flow:

The chosen gas dictates the optimal nozzle diameter and the required pressure and flow rate settings on your machine's gas console. Larger nozzles are typically used with nitrogen for higher flow, while smaller nozzles are common for oxygen cutting. Always consult your machine manual and cutting parameter tables for recommended settings based on material, thickness, gas, and nozzle.

Conclusion: Precision Requires the Right Partner

Choosing the correct assist gas is not a one-size-fits-all decision; it's a strategic choice based on material, thickness, desired edge quality, and cost. Understanding the roles of oxygen, nitrogen, and argon empowers you to unlock the full potential of your fiber laser cutting machine.

As experts in fiber laser technology, [Your Company Name] provides comprehensive support, including detailed cutting parameter recommendations and guidance on gas selection for our machines. Contact our technical team today to discuss optimizing your cutting processes and achieving superior results with the perfect gas partner. Let us help you cut smarter, not harder.