Application of Fiber Laser Equipment in Modern Manufacturing Industry

Source:razorteklaser Time:2025-09-17

In the trend of modern manufacturing towards intelligence, precision and green, innovative technology has become the core engine driving industrial upgrading. Fiber laser technology, with its outstanding performance and wide applicability, is profoundly changing the traditional outlook of the metal processing field.

The series of optical fiber laser cutting machine, optical fiber laser welding machine and optical fiber laser cleaning machine, with their outstanding characteristics of high efficiency, accuracy and environmental protection, provide key solutions for many industry customers, and enable the infinite possibilities of modern manufacturing industry.

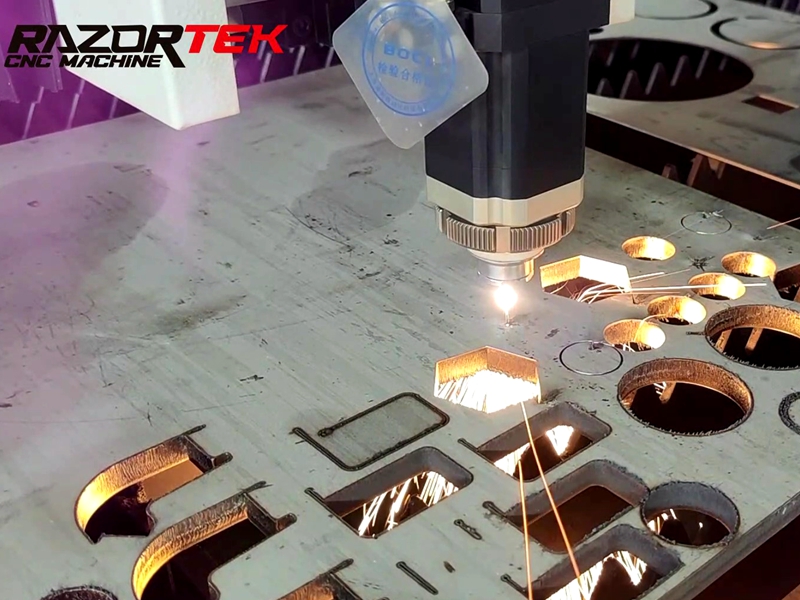

Fiber Laser Cutting Machine: Efficiency and Accuracy Limits for Reconfigured Sheet Metal Machining

In the modern sheet metal processing field, compared with the traditional processing mode, the optical fiber laser cutting technology has an incomparable advantage, and is widely used in sheet metal manufacturing, chassis and cabinet, elevator parts, auto parts, kitchen and bathroom hardware, advertising signs and other industries for metal plate blanking.

Application advantages:

1. Extremely precise cutting: Extremely high energy density and excellent beam quality can realize the cutting accuracy of micrometer level. The notch is smooth and burr-free, greatly reducing the requirements of subsequent secondary processing.

2. Extraordinary production efficiency: the cutting speed is very fast. With the automatic loading and unloading system, 24-hour uninterrupted production can be realized, significantly improving the capacity and reducing the cost of a single piece.

3. Excellent processing flexibility: without die opening, any complex graphics can be quickly switched through software, especially suitable for multiple varieties, small batches, customized flexible production mode.

4. Extensive material adaptability: it can effectively cut carbon steel, stainless steel, aluminum alloy, brass and other metal materials to meet diversified processing requirements.

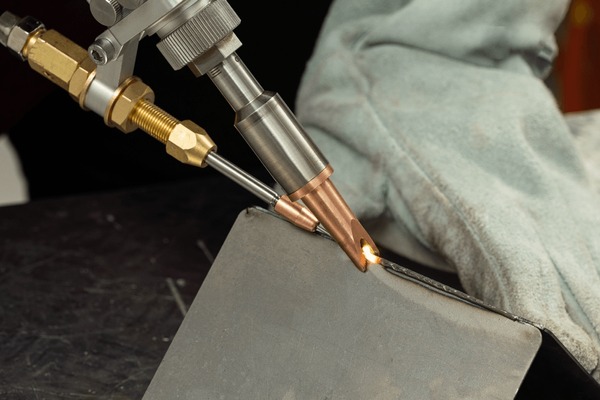

Fiber laser welding machine: leading the technical revolution of precise connection

Fiber laser welding establishes a new benchmark for high requirements and high quality connection process, and is the key technology to achieve lightweight, integration and high performance of products.

Core application field:

Precision application in new energy vehicle battery module (battery Busbar welding), motor, sensor, medical device, consumer electronics, jewellery and other fields with high welding quality requirements.

Application advantages:

1. Small heat affected zone: highly concentrated energy, deep and narrow welding seam, minimal thermal deformation, and perfect maintenance of workpiece geometry and mechanical properties.

2. High weld strength: there is no electrode pollution during welding, the weld is clean and dense, the strength is often higher than the base metal, and the welding trace is flat and beautiful.

3. Non-contact remote welding: it can be remotely scanned by the robot arm, easy to realize automatic integration, especially suitable for complex three-dimensional tracks and inaccessible corners.

4. Strong process compatibility: it can realize pulse, continuous and other welding modes, and can easily meet multiple process requirements such as overlay welding, butt welding and seal welding.

Fiber laser cleaning machine

Fiber laser cleaning is a "green" surface treatment technology that is rapidly replacing traditional high pollution, high energy consumption cleaning methods.

Core application fields:

Mainly used in pre-treatment before welding/spraying, mould maintenance, tyre mould cleaning, rust removal and paint removal, cultural relics restoration, parts renewal and other fields.

Application advantages:

1. Green, environmental-friendly and pollution-free: no chemicals, abrasives or media are required, no waste gas and waste water are discharged, only a small amount of stripped dust can be easily collected by dust pumping equipment, which is environmentally friendly.

2. Precise and controllable base material: Through parameter adjustment, the surface coating, oil stain and oxide layer can be accurately removed, and the metal matrix itself can be perfectly retained, which is difficult to be achieved by traditional sand blasting.

3. Low operation cost and convenient operation: the equipment is stable and durable, with few consumables and obvious comprehensive cost advantages for long-term use. Flexible hand-held or automated operation, easy integration into existing production lines.

4. Safety and high efficiency: non-contact, no grinding process, no mechanical stress on the workpiece, safer operation and high cleaning efficiency.

From precision cutting to solid welding to green cleaning, fiber optic laser technology is unleashing its huge potential in every link of modern manufacturing. It is not only a tool to improve product quality and productivity, but also a key partner for enterprises to realize intelligent upgrading and implement sustainable development strategies.

As a professional manufacturer of fiber laser equipment, Razotek has always been committed to providing customers with high-performance and highly reliable fiber laser cutting machine, welding machine and cleaning machine complete solutions. We are looking forward to working with you to explore more applications of fiber laser technology and help your company win the first chance in the fierce market competition, so as to create a better future of intelligent manufacturing.