Application of Fiber Laser Equipment in Automobile Industry

Source:razorteklaser Time:2025-09-19

In the process of automobile industry moving towards lightweight and intelligence, optical fiber laser technology is becoming the core force to promote body manufacturing process innovation. As the key technology of advanced manufacturing, fiber laser equipment has been widely used in the field of automobile manufacturing due to its high precision, high efficiency and non-contact processing characteristics.

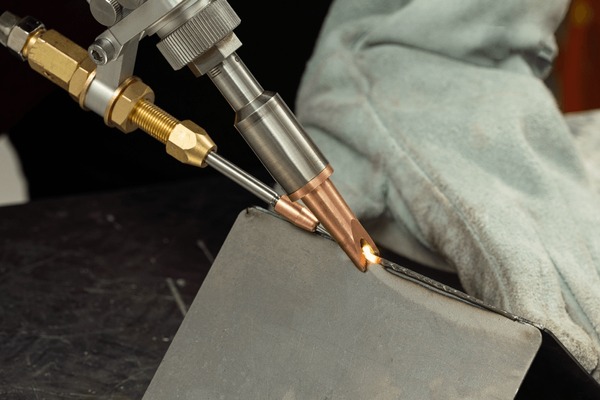

Fiber laser welding machine: the art of precise connection

Laser welding plays an important role in the manufacture of automobile body, especially in the welding of body frame structure, such as the connection of head cover and side body. This technology not only improves design flexibility, reduces costs, increases stiffness and enhances market competitiveness.

Its core strengths include:

1. High precision: excellent beam quality for micron level welding.

2. High efficiency: high electro-optical conversion efficiency, far superior to traditional YAG laser.

3. Non-contact welding: it can be remotely operated through flexible optical fiber transmission, and is applicable to complex structures or inaccessible parts.

4. Strong material adaptability: high reflective materials such as copper, aluminum and titanium can be welded, and dissimilar metals such as steel-aluminum and copper-time can be welded.

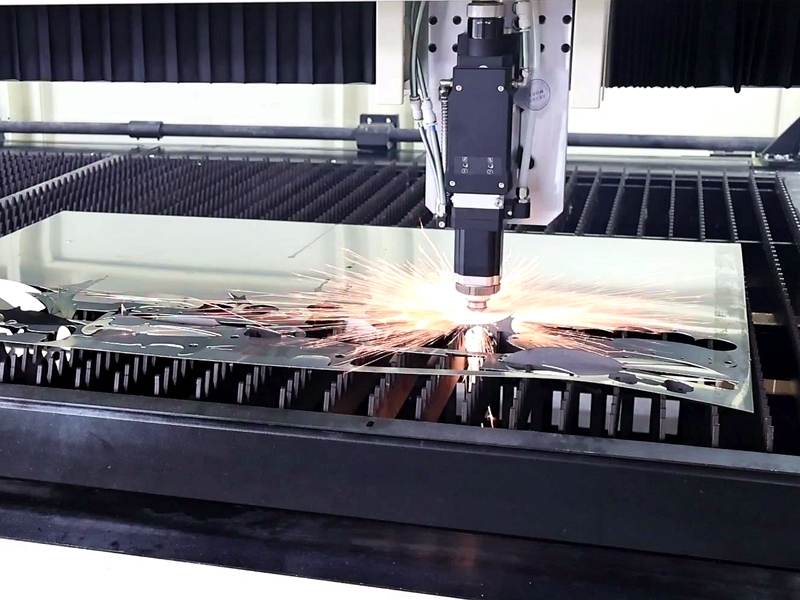

Fiber Laser Cutting Machine: Accurately reshape automotive materials

Laser cutting technology has been widely used in auto parts, auto body, carriage, chassis, head and other aspects, basically covering all application fields in the auto manufacturing industry.

Application advantages:

Laser cutting has higher cutting accuracy, lower roughness and higher production efficiency. In particular, the automobile industry has higher requirements for the refinement of parts. In the fine cutting field, laser cutting has more advantages than traditional cutting.

Application of fiber laser cutting technology in automobile industry:

1. Manufacturing of body structural parts

Optical fiber laser cutting can accurately cut high-strength steel plates, aluminum alloys and other materials, and is used to manufacture body frameworks, support beams, cross beams and exterior trimming parts (such as doors and engine covers), so as to realize high-precision cutting of complex shapes.

2. Production of electronic and electrical parts

When manufacturing electronic control unit shell, instrument panel panel and other parts, optical fiber laser cutting can accurately cut metal or plastic materials to meet the accuracy and function integration requirements of electronic parts.

3. Processing of power assembly parts

The technology is used for precision cutting of metal materials such as engine cylinder block and transmission housing to ensure the machining accuracy and efficiency of power assembly system.

4. Production of lightweight parts

When cutting aluminum alloy wheels, roofs and other parts, the fiber laser can process special materials such as ultra-hard alloy to help the lightweight design of automobile parts.

5. Special process requirements

For example, in the processing of thermoformed parts of new energy vehicles (such as anti-collision beams and chassis parts), fiber laser technology realizes fast melting and precise cutting through high power density, replacing traditional die stamping process.

Razortek been a leading manufacturer of fiber optic laser equipment for many years, providing high-performance laser solutions to many automotive manufacturers and parts suppliers to help customers improve production efficiency and product quality.